Sustainability is changing how manufacturers work. Companies want to reduce their carbon footprint, conserve resources, and use environmentally friendly methods. At Wertzbaugher Services, we offer many fabrication and welding solutions. Aluminum welding is one of them, and while it is not our main focus, it plays an important role in supporting sustainability.

Why Aluminum Welding Helps Sustainability

Aluminum is light, strong, and recyclable. These qualities make it a great choice for eco-friendly manufacturing. Using aluminum can lower energy consumption in transportation and production. When paired with sustainable welding practices, aluminum supports a circular economy by reducing waste and conserving resources.

Even though aluminum welding is only part of what we do, it helps us deliver high-quality results while supporting customers who want greener solutions.

How Wertzbaugher Services Uses Aluminum Welding

We use aluminum welding where it makes sense for strength, weight reduction, and environmental impact. Here are a few examples:

- Trailers and Transport Equipment: Aluminum welding helps us build lighter trailers and truck bodies. Lighter equipment means less fuel use, lower energy costs, and a smaller carbon footprint.

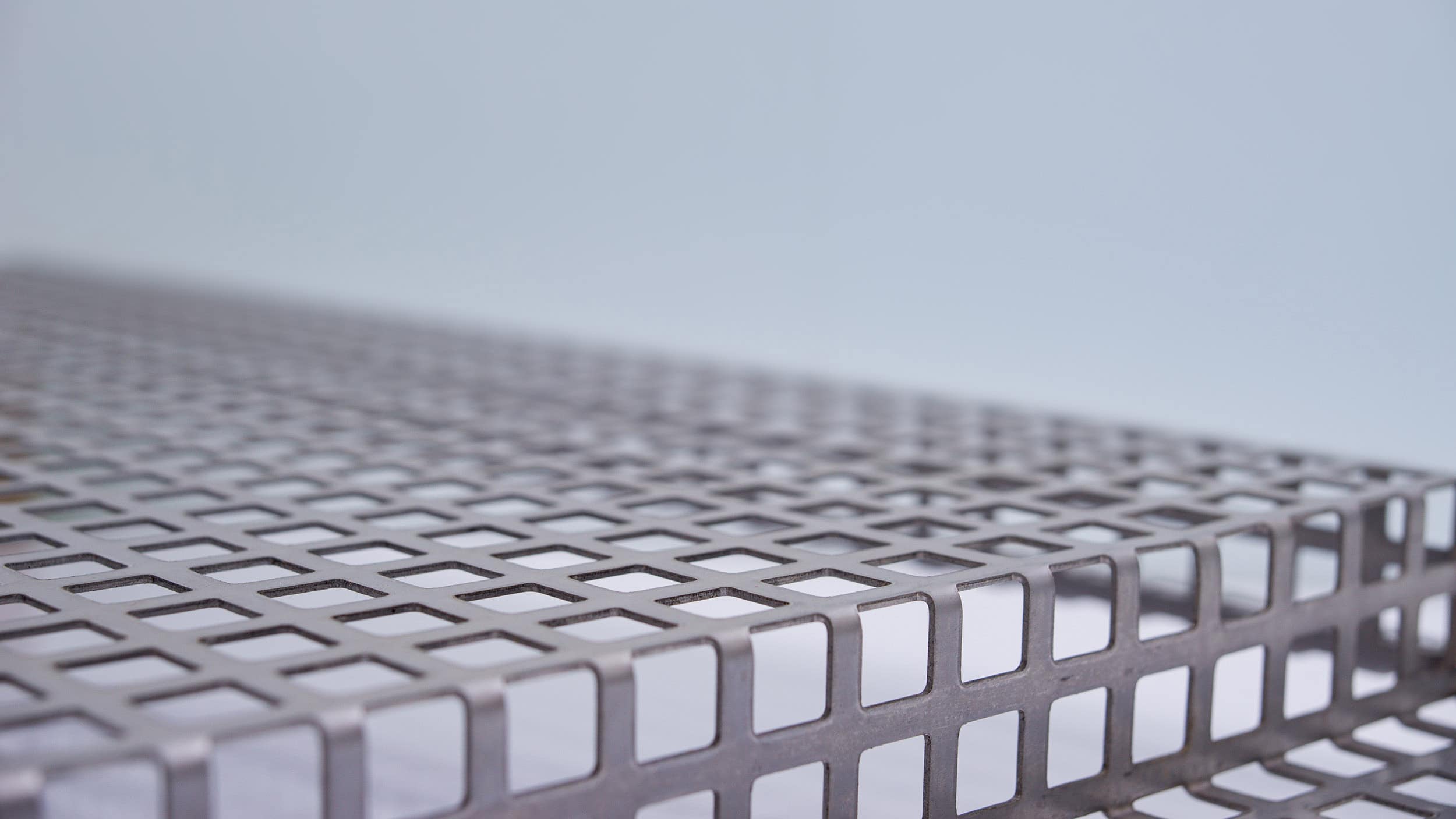

- Specialized Fabrication Projects: In some industrial applications, aluminum offers durability without extra weight. We use advanced welding techniques like friction stir welding and inert gas shielding to ensure precision and reduce waste.

- Laser Welding: Wertzbaugher Services leverages advanced laser welding technology to deliver superior speed, precision, and quality in every project. Laser welding is widely recognized as the preferred method for aluminum fabrication due to its accuracy and efficiency. Our facility is equipped with state-of-the-art, in-house laser welding systems, ensuring consistent, high-performance results that meet the most demanding industry standards.

These projects show how aluminum welding can complement other fabrication methods to create solutions that are functional and environmentally responsible.

Supporting Sustainable Manufacturing Practices

Aluminum welding is just one part of our approach, but its impact matters. Lightweight aluminum structures reduce energy consumption during transport. Recycling scrap aluminum and reusing components supports the circular economy. We also use energy-efficient welding systems and fume extraction technologies to reduce harmful fumes and improve workplace safety.

The Bigger Picture

Sustainable manufacturing is not about one material or one process. It is about making smart choices across the board. At Wertz Services, we combine aluminum welding with other advanced techniques to deliver high-quality, energy-efficient solutions that reduce environmental impact. Whether it is steel, aluminum, or other materials, our goal is the same: minimize waste, conserve resources, and help customers reduce their carbon footprint.

Aluminum welding may not be our main focus, but it plays an important role in creating lighter, stronger, and more sustainable products. By including this capability in our broader fabrication services, Wertzbaugher Services supports environmentally friendly practices that benefit both manufacturers and the planet.

Lisa Wertzbaugher is a business development consultant with over 15 years of experience in sales, strategy, and leadership across service, medical device, and manufacturing industries. She leads her own consulting practice focused on growth strategy, sales training, and transition planning, and co-owns Wertzbaugher Services, a fabrication and welding shop in West Liberty, Iowa. Lisa serves as 2nd Vice Chair of the Board of Directors for the Fabricators & Manufacturers Association and contributes regularly to The Tube and Pipe Journal and The Fabricator, sharing insights on business leadership and industry trends.