Understanding Battery Racks

Battery racks are essential components in renewable energy systems. They provide a safe, organized way to store batteries, making it easier to manage energy storage for solar, wind, and hybrid projects. A battery rack is more than just a shelf—it’s a system designed to support batteries securely, protect them from environmental hazards, and ensure efficient operation.

Types of Battery Racks

There are several types of battery racks, each suited to different needs:

- Energy Storage Rack: Used to hold batteries for storing electricity generated by renewable sources.

- Industrial Battery Rack: Built for large-scale projects, these racks are strong and durable, often used in utility or data center environments.

- Modular Battery Rack: These racks can be expanded or reconfigured as energy needs change, making them ideal for growing projects.

- Battery Mounting System: Refers to the hardware and design that keeps batteries stable and secure.

- Battery Enclosure: Provides extra protection against weather, dust, and accidental contact.

Why Custom Battery Racks?

Every renewable energy project is unique. Standard racks may not fit the available space, battery type, or safety requirements. Custom battery racks are designed to match the specific needs of a project, including:

- Space Optimization: Custom racks make the best use of available room, whether in a small solar shed or a large industrial facility.

- Safety Features: Acid-proof coatings, spill containment, and seismic anchoring help prevent accidents and meet regulatory standards.

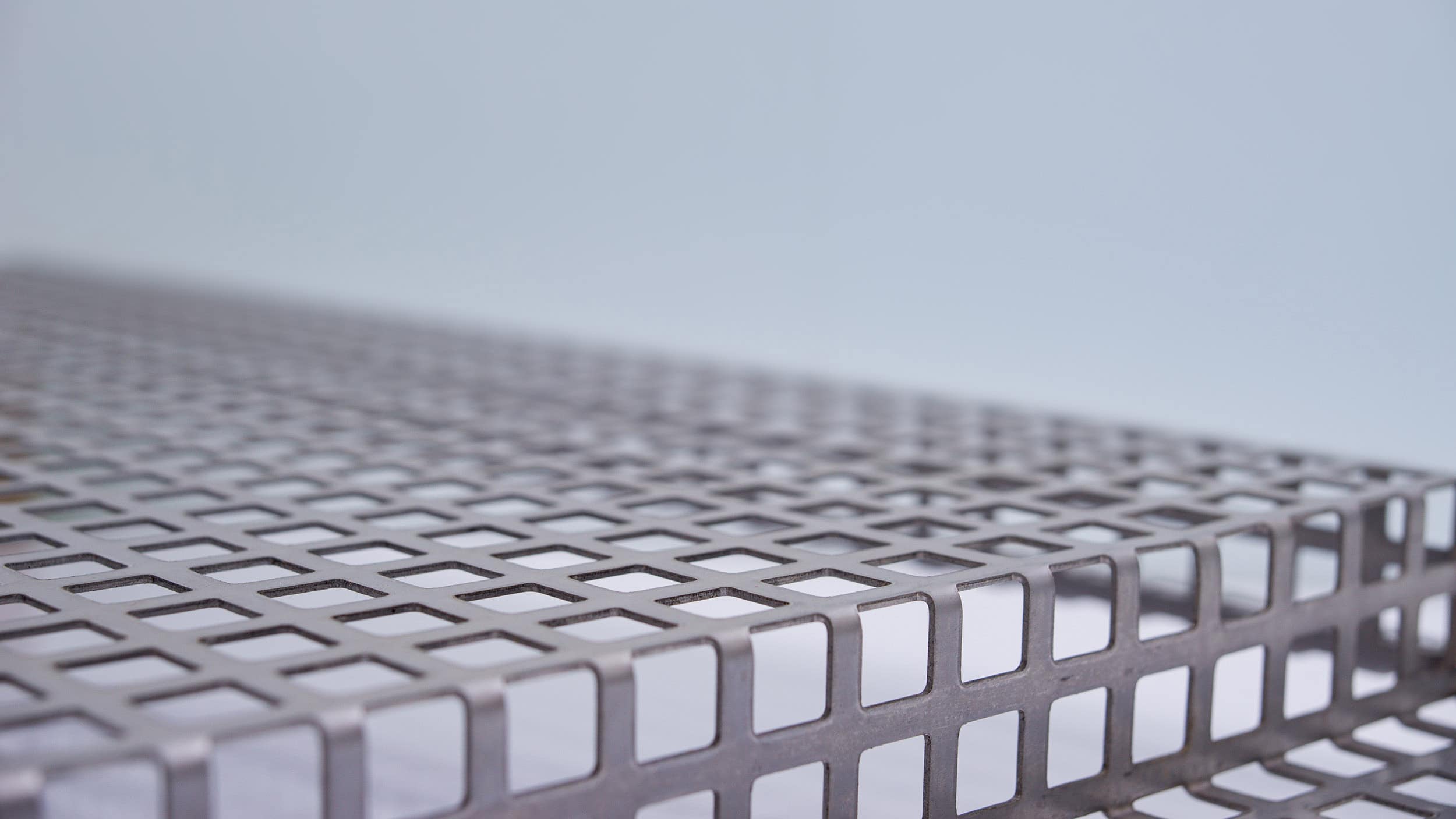

- Material Choices: Racks can be made from powder-coated steel, stainless steel, or galvanized metal for corrosion resistance and durability.

- Easy Installation: Custom racks are designed for straightforward assembly and integration into existing systems.

Key Considerations for Battery Rack Installation

Proper installation is crucial for safety and performance. Here are some important factors:

- Room Layout: The rack should fit the space and allow for easy access to batteries for maintenance.

- Cable Management: Good racks include features for organizing cables, reducing clutter and improving safety.

- Code Compliance: Racks must meet local and national safety codes, including fire protection and electrical standards.

- Flexibility: Modular designs allow for future expansion or changes in battery technology.

Applications in Renewable Energy

Battery racks are used in many renewable energy settings:

- Solar Farms: Store large battery banks to capture solar energy for use at night or during cloudy periods.

- Wind Energy Sites: Hold batteries that store power generated by wind turbines.

- Hybrid Systems: Combine solar, wind, and backup power, requiring flexible storage solutions.

- Industrial Facilities: Support backup power systems for utilities, telecom, and data centers.

Maintenance and Longevity

A well-designed battery rack helps extend the life of batteries by keeping them secure and protected. Regular inspections and maintenance are important to check for corrosion, loose connections, or damage. Choosing the right rack materials and design can reduce maintenance needs and improve overall system reliability.

Battery racks play a vital role in renewable energy projects by providing safe, organized, and scalable storage for batteries. Custom solutions offer flexibility, safety, and efficiency, ensuring that energy storage systems perform reliably over time. Whether you’re working on a small solar installation or a large industrial project, understanding the options and features of battery racks can help you make informed decisions for your energy storage needs.

Lisa Wertzbaugher is a business development consultant with over 15 years of experience in sales, strategy, and leadership across service, medical device, and manufacturing industries. She leads her own consulting practice focused on growth strategy, sales training, and transition planning, and co-owns Wertzbaugher Services, a fabrication and welding shop in West Liberty, Iowa. Lisa serves as 2nd Vice Chair of the Board of Directors for the Fabricators & Manufacturers Association and contributes regularly to The Tube and Pipe Journal and The Fabricator, sharing insights on business leadership and industry trends.