Wilson trailers are uniquely engineered, which means they require specialized repair techniques—especially for aluminum welding, grain trailer repair, frame enhancement, and rust removal. Using genuine Wilson parts and working with a shop experienced in Wilson’s construction ensures long‑lasting repairs, better performance, and less downtime. Skilled, precision‑based repair is the key to protecting your investment and keeping your fleet moving.

Wilson trailers are built for durability, but even the strongest equipment needs expert attention over time. Whether you’re hauling grain across state lines or transporting commercial materials, Wilson trailer repair demands specialized knowledge. These trailers use distinct engineering and materials, and only an experienced shop can deliver repairs that last. The difference between a quick fix and a true repair often comes down to expertise.

Why Wilson Trailers Need Specialized Attention

Wilson trailers are not like other brands. Their frame construction, aluminum components, and precise engineering require repair techniques tailored to their specific design. A generic, one‑size‑fits‑all approach simply doesn’t work.

Grain Trailer Repair

Grain trailers, in particular, take constant abuse—weather exposure, corrosive materials, and repeated loading cycles. Even well-maintained Wilson grain trailers eventually show wear. The question isn’t if they need repair, but whether that repair is done correctly the first time.

Using standard Wilson parts ensures proper fit, structural integrity, and long‑term durability. While generic parts may seem cheaper initially, they often fail sooner, increasing downtime and costs. Genuine Wilson components paired with skilled fabrication protect your trailer’s longevity.

Aluminum Trailer Repair: Precision Matters

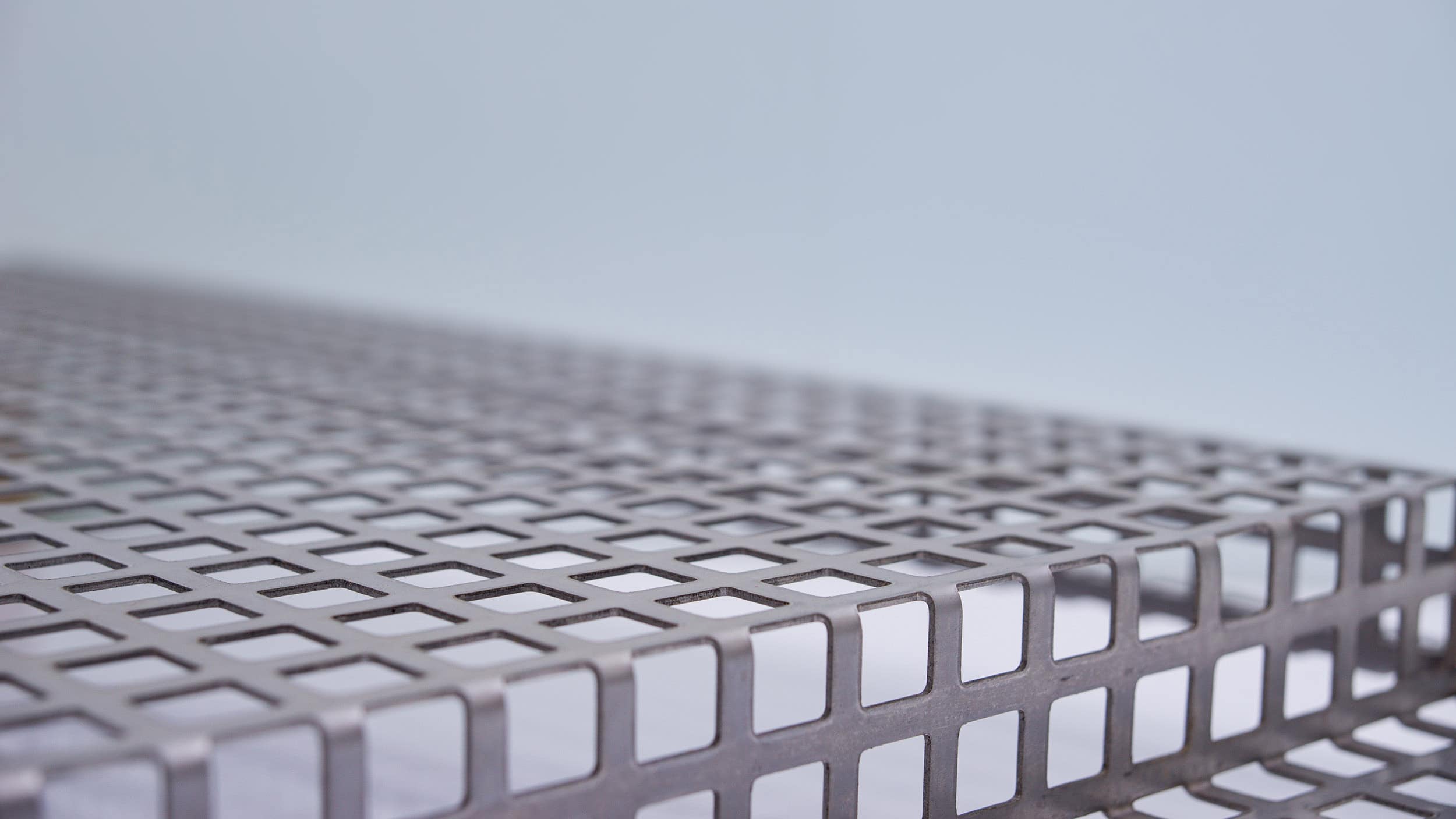

Aluminum repair is a specialty in itself, and not every shop is equipped for it. Wilson uses aluminum extensively for its weight savings and corrosion resistance, making precision repairs essential for maintaining those advantages.

Specialized Aluminum Welding

Aluminum welding differs significantly from steel welding. It requires:

- Careful temperature control

- Proper shielding gases

- Correct filler materials

- Advanced equipment

An inexperienced welder can easily weaken the structure, causing cracks or failure under load. Our shop uses advanced aluminum‑specific welding methods to meet or exceed the standards of Wilson’s original manufacturing.

Frame Enhancements

High‑stress areas on Wilson trailers sometimes need reinforcement. Properly designed frame enhancements extend service life without compromising weight. This customization requires both aluminum expertise and a deep understanding of Wilson’s engineering.

Rust Removal and Prevention: Protecting Your Investment

Although Wilson trailers rely heavily on aluminum, steel components—axles, suspensions, fasteners—remain vulnerable to rust.

Rust isn’t just cosmetic. It spreads, weakens structural parts, and shortens your trailer’s lifespan.

Effective rust removal includes:

- Identifying the true source of corrosion

- Removing rust completely, not just sanding the surface

- Applying long‑term prevention strategies, such as coatings or component upgrades

For grain trailers, moisture from grain combined with road salt creates ideal conditions for corrosion. Regular inspections and proactive rust prevention stop small issues from becoming major failures.

Custom Repairs Built on Wilson Expertise

No two trailers show damage in the same way. Usage, cargo, environment, and maintenance all shape repair needs.

This is why using standard Wilson parts for custom repairs is so important. We fabricate solutions that maintain Wilson’s engineering integrity—respecting load distribution, stress points, and material properties.

Improving Beyond the Original Design

Sometimes great repair work means enhancing the original structure:

- Reinforcing high‑wear zones

- Upgrading connection points

- Modifying components for better durability

These improvements require fabrication skill and a detailed understanding of how Wilson trailers operate under real‑world conditions.

The Difference Experience Makes

When your Wilson trailer is down, your operation slows. Rushing to get a trailer back on the road with poor-quality repairs only leads to more downtime later.

Expert Wilson trailer repair includes:

- Accurate diagnostics

- Quality Wilson parts

- Skilled aluminum and steel fabrication

- Thorough testing before return to service

Grain trailers depend on reliable repairs during harvest season. Aluminum trailers require exact welding to maintain strength. Rust removal must be complete and preventive. Frame enhancements must preserve load capacity and safety.

Whether your trailer needs routine maintenance or major structural work, choosing an experienced shop ensures repairs that last. At our facility, we combine advanced welding capabilities, genuine Wilson parts, and decades of repair expertise.

Your Wilson trailer is a major investment—protecting it means more than just fixing damage. It means understanding Wilson’s engineering and maintaining it to the same high standards. That’s the foundation of truly dependable Wilson trailer repair.

Lisa Wertzbaugher is a business development consultant with over 15 years of experience in sales, strategy, and leadership across service, medical device, and manufacturing industries. She leads her own consulting practice focused on growth strategy, sales training, and transition planning, and co-owns Wertzbaugher Services, a fabrication and welding shop in West Liberty, Iowa. Lisa serves as 2nd Vice Chair of the Board of Directors for the Fabricators & Manufacturers Association and contributes regularly to The Tube and Pipe Journal and The Fabricator, sharing insights on business leadership and industry trends.